Shaping Transparent Glass is Made

Fast, Affordable, and Energy-Efficient

3D printing is shaping the future manufacturing. In 2020 about 2 million 3D printers were sold. They print plastics, metals, even ceramics, but none could print glass.

However, the demand of complex glass products grows continuously in medical, optics, aerospace, solid state battery, art, jewelry, and other markets.

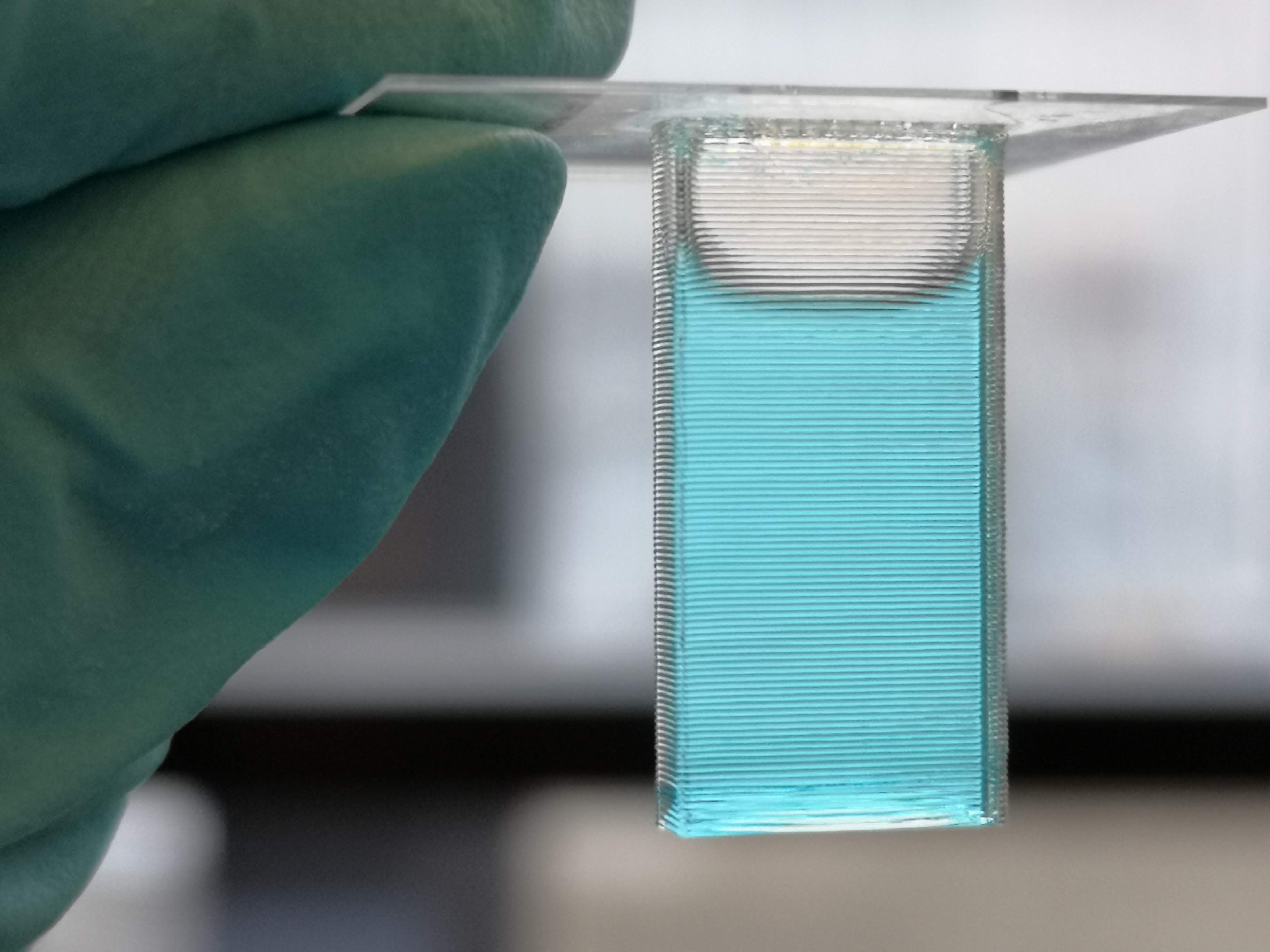

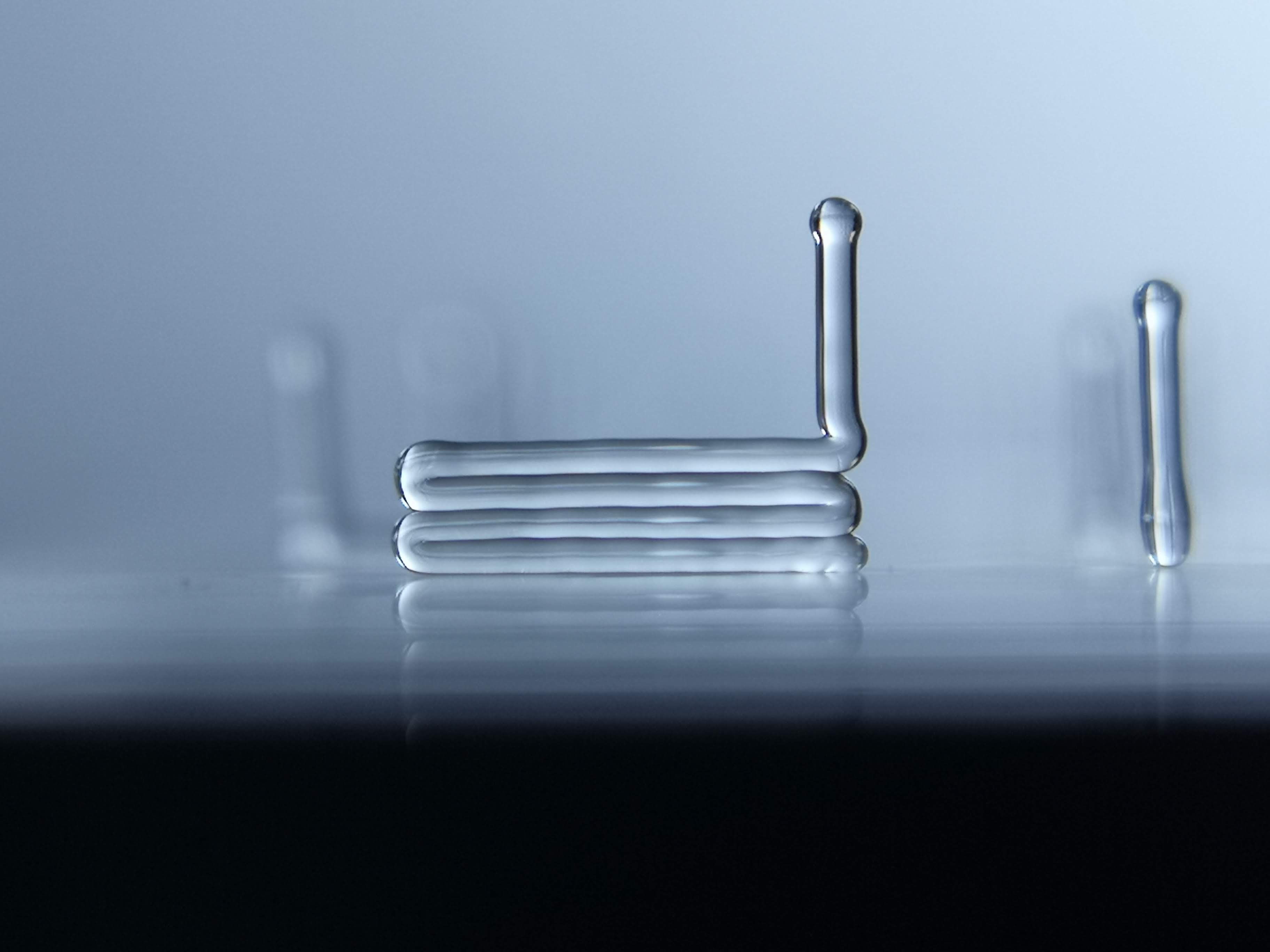

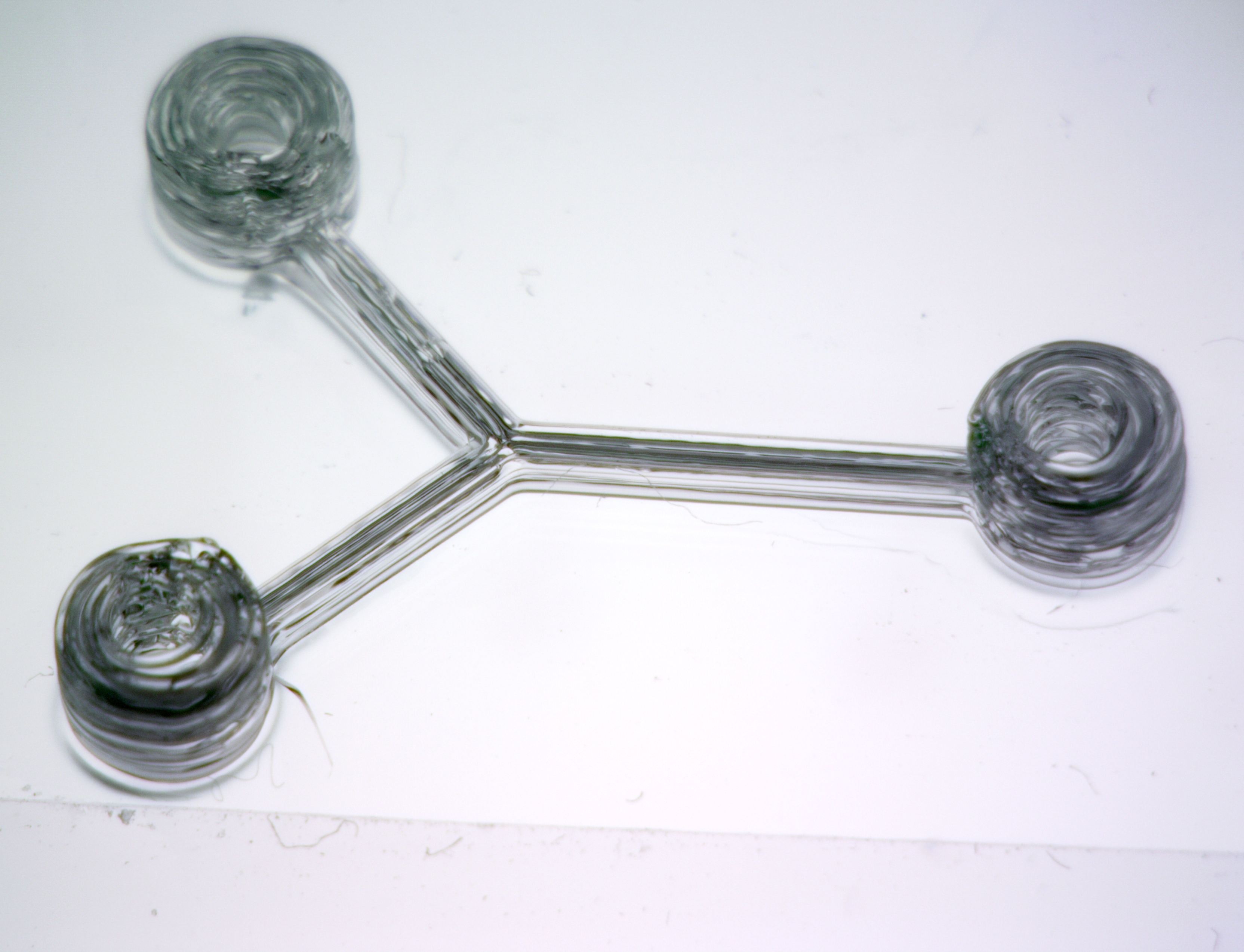

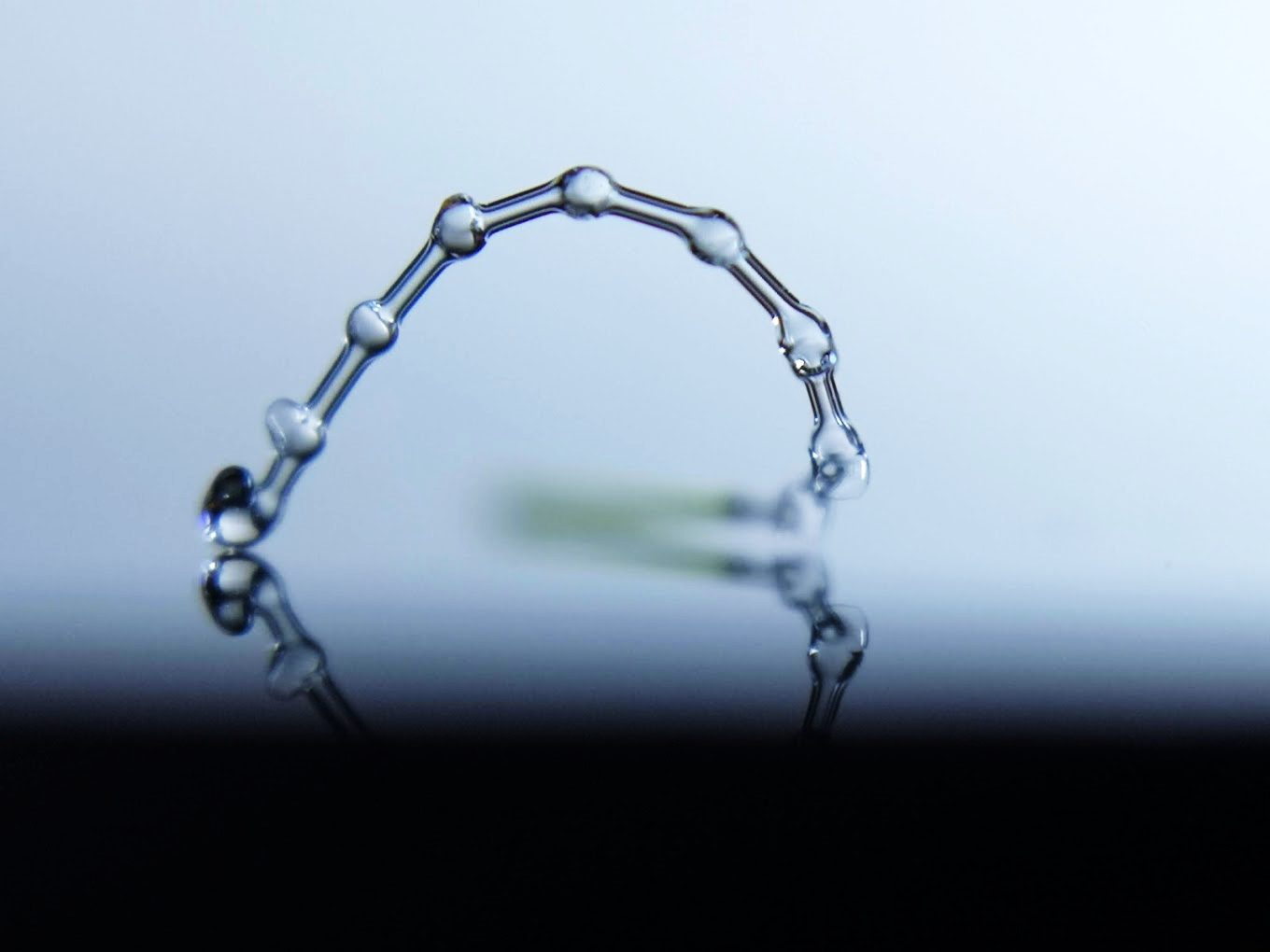

Nobula® glass 3D printer allows complex 3D structures to be produced in glass. With our Direct Glass Laser Deposition (DGLD®) technology, 3D printing glass is as easy as printing plastic!

Glass Foundry on your desk

Glass 3D Printer

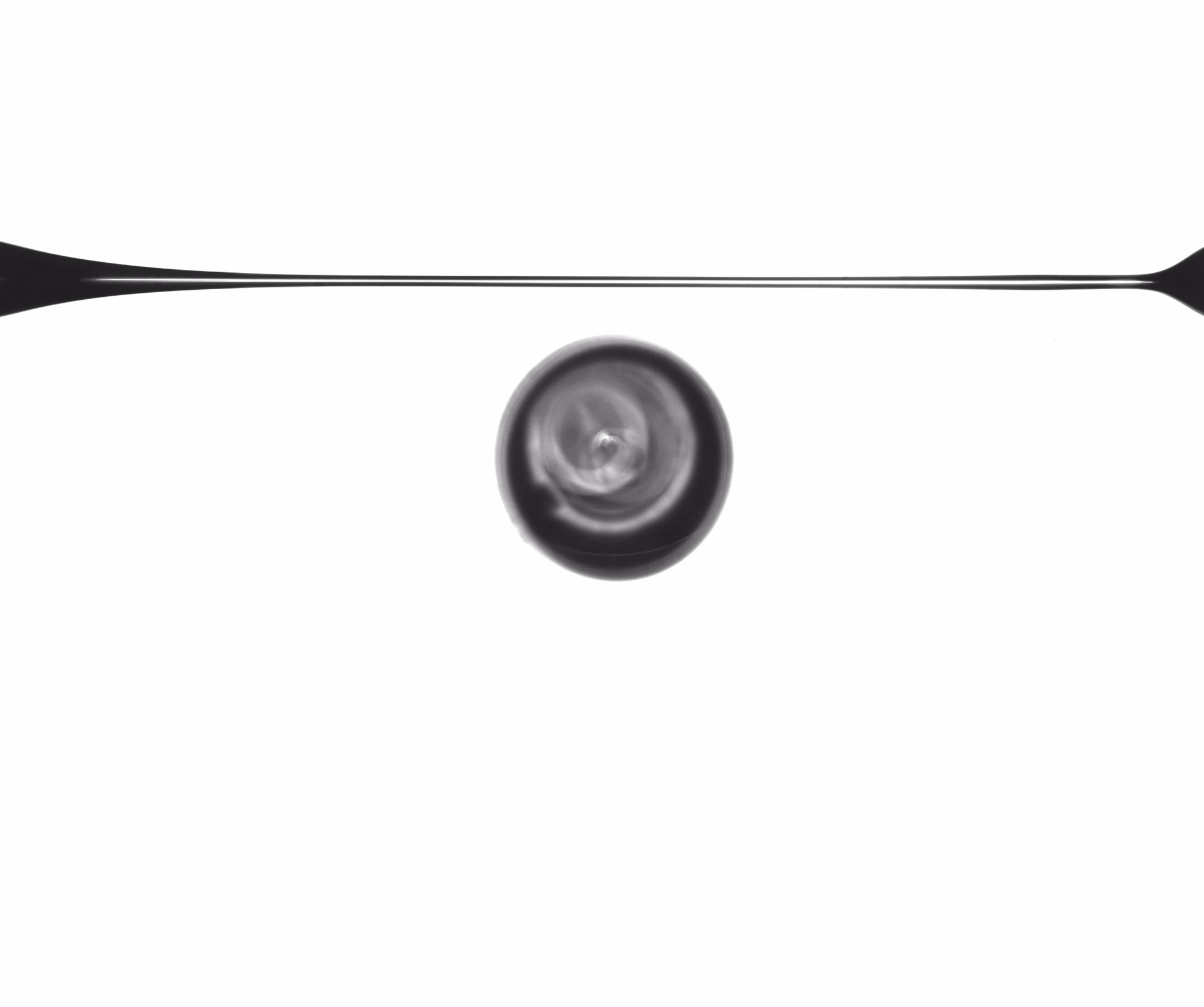

Outstanding Glass Printing quality and extreme energy efficiency at 2000 °C thanks to the novel Direct Glass Laser Deposition (DGLD®) technology

Unique Glass Filament

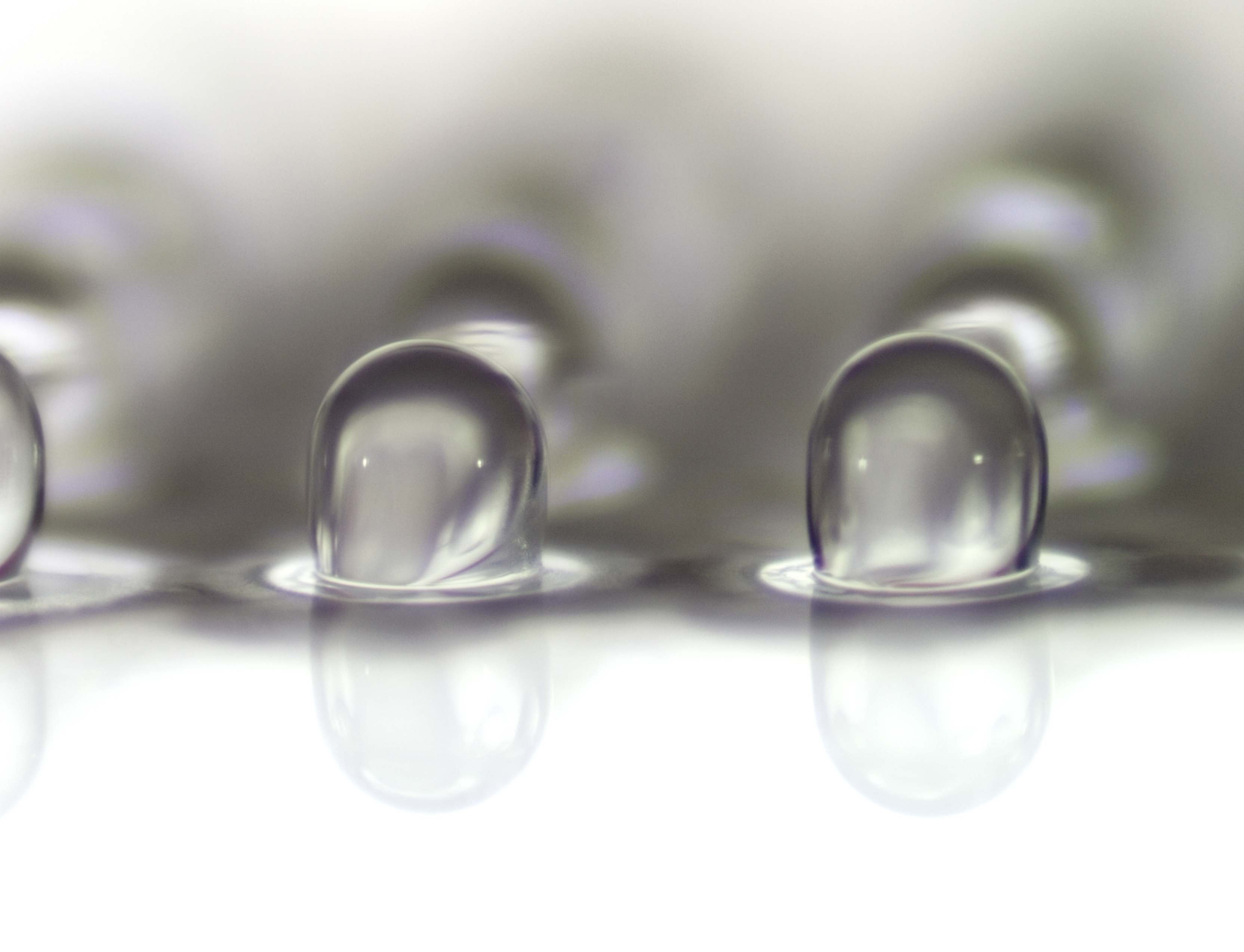

Specially designed glass filaments maximize the printing flexibility and consistency. Innovative Multi-component filaments open up diverse applications

3D Printing Service

Printing as a Service (PaaS). Besides the printer and filament, we offer tailor-made glass 3D printing service from development to production, hardware to software

Glass Foundry on your desk

Glass 3D Printer

Outstanding Glass Printing quality and extreme energy efficiency at 2000 °C thanks to the novel Direct Glass Laser Deposition (DGLD®) technology

Unique Glass Filament

Specially designed glass filaments maximize the printing flexibility and consistency. Innovative Multi-component filaments open up diverse applications

3D Printing Service

Printing as a Service (PaaS). Besides the printer and filament, we offer tailor-made glass 3D printing service from development to production, hardware to software